Remember, Vikings do it better.To successfully solder surface mount components to a circuit board, the heat should be transferred to the solder alloy paste until its temperature reaches a molten point (217☌ for SAC305 lead free solder). With an automatic damper on each stack, they can all be connected into a single main exhaust, yet they all are being held to a constant air flow, each set for the desired air flow of the oven, chamber, or room exhaust they serve.

The cost of each exhaust port going through the roof can be a huge expense. In fact they pay for themselves many times over in energy costs if properly designed into the building ventilation system when you considered the heat/AC losses that several uncontrolled exhausts present. This is just one example, there are many regulated-pressure automatic exhaust damper systems that are really not that expensive. This would include heating and AC systems as well as reflow ovens, convection ovens, test chambers, number of doors used, number of dock doors open/closed, and the list goes on and on.įor something like this, you need a real Viking to solve the problem. If you have multiple stacks in a building and each has its own blower, the building pressure will change depending on how many individual stacks are being used. The reason is the same as the example of multiple vents connected to a main exhaust plenum, variation in building pressure. This will NOT provide a stable air flow or stable pressure, indeed you will see just the opposite. If the reflow oven exhaust flow is too high, the oven may be "sucking" air into its doors and them contaminating your reflow zone with unwanted oxygen from air.Ī single-stack exhaust for each oven certainly does not work very well. Talking about reflow ovens using nitrogen. The only thing I could add to that is no matter how you're exhausting your reflow oven. Make sure that you put in provisions to take the duct apart and clean it. But yes, high tempered and cleanable, you know, all the manufactures do their best to put filters for flux-capture inside, but always anticipate the possibility of some flux getting into the duct and condensing somewhere. The only thing I want to add is when you do your ducting, make sure that the ducting you're using to connect from the oven to the rest of your exhausting system is rated for the proper temperature for the reflow oven.ĭepends upon the way the oven is ducted internally and so forth. That it doesn't vary over time such as when the people down at the end of the exhaust duct turn on the spray booth or something and the static pressure, and therefore the flow rate, changes and your oven thermal process is upset. And what you're really concerned about is getting the proper volumetric flow rate and that it's stable. The key is pressure is only an indication of flow rate. Often you see these little red mercury or alcohol manometers that they use in duct work. be using to performs these tests?įor measuring static pressures, it's just any kind of a pressure gauge or manometer. If they give you a flow rate, then you go to your piping and make the conversion using standard duct flow procedures. But the bottom line is you go to the manufacturer. Then the static pressure, if it's outside the oven, to create that flow rate is going to depend upon the geometry and dynamics of your exhaust piping. Some ovens may give you a pressure tap inside the oven within their known piping. The real critical parameter that most ovens will specify is a flow rate in cubic feet per minute or cubic meters per hour or some other volumetric flow rate.

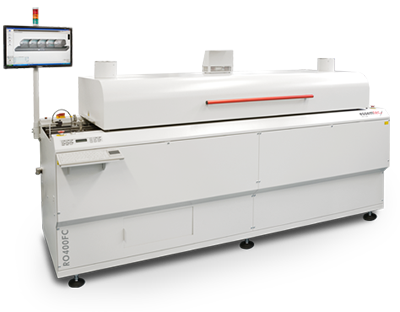

You've got to have the right exhaust and it's important. Well, certainly measuring pressure in an exhaust system is one way to quantify it. At what exhaust pressure normally should the oven be measured at? You had mentioned about proper exhausting of the reflow oven. We're here to answer your process questions regarding SMT and the associated realm. This is Jim Hall and Phil Zarrow, the Assembly Brothers, pick and place or place and pick. He is a pioneer in the science of reflow. He has vast experience in SMT equipment, materials and processes.Ī Lean Six-Sigma Master Blackbelt, Jim has a wealth of knowledge in soldering, thermal technology, equipment and process basics. With over 35 years experience in PCB assembly, Phil is one of the leading experts in SMT process failure analysis. Process Troubleshooting, Failure Analysis, Process Audits, Process Set-upĬEM Selection/Qualification, SMT Training/Seminars, Legal Disputes What is the proper exhaust pressure for a reflow over? Where should we measure the pressure? How should we measure pressure?īoard Talk Board Talk is presented by Phil Zarrow and Jim Hall of ITM Consulting. Proper Exhaust Pressure for Reflow Ovens? To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video.

0 kommentar(er)

0 kommentar(er)